-

Shutter Door Roll Forming Machine

-

Door Frame Roll Forming Machine

-

Roof Panel Roll Forming Machine

-

Tile Roll Forming Machine

-

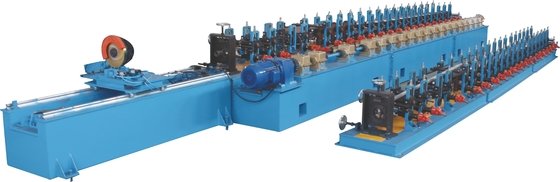

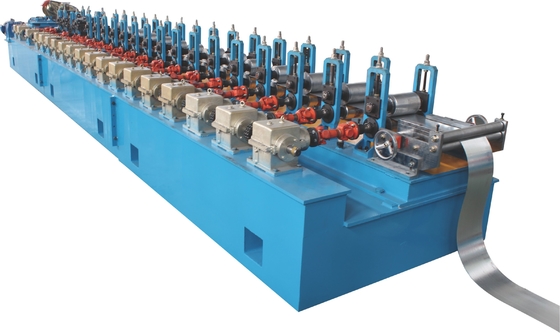

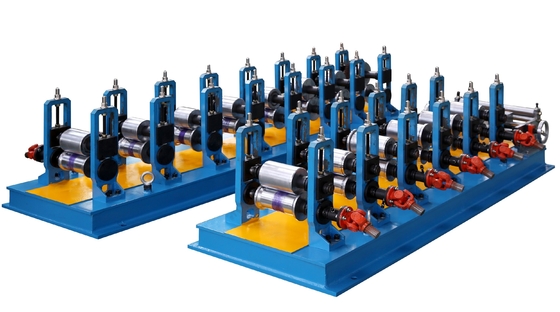

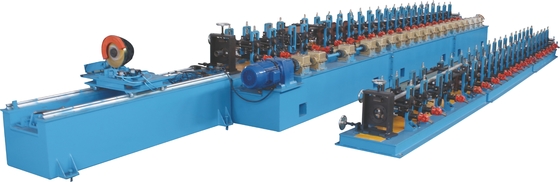

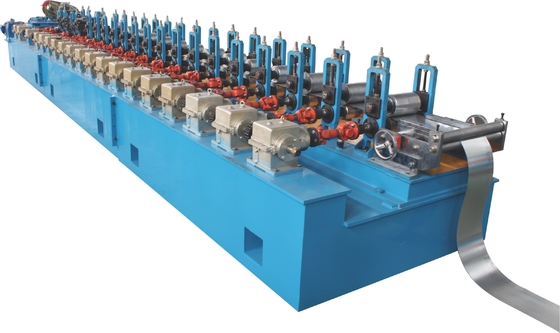

Round Pipe Roll Forming Machine

-

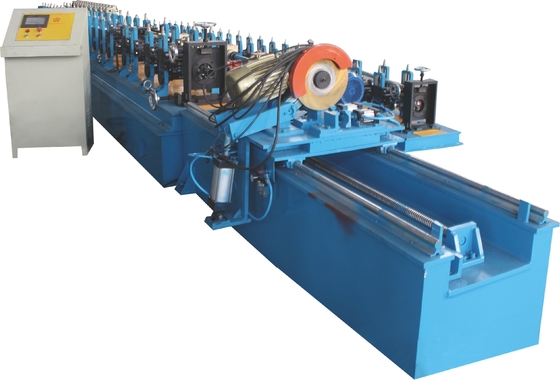

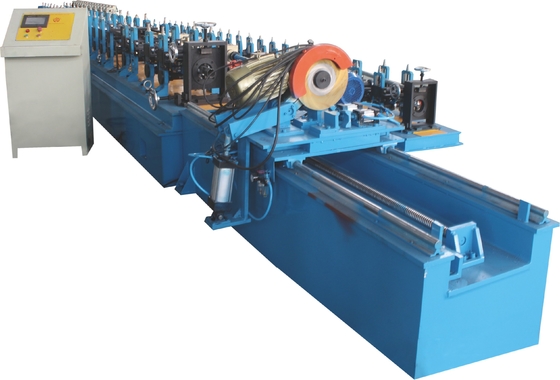

Purlin Roll Forming Machine

-

Guard Rails Roll Forming Machine

-

Double Layer Roll Forming Machine

-

Cold Roll Forming Machine

-

Floor Deck Roll Forming Machine

-

Metal Embossing Machine

0.4~1.0mm Octagonal Tubes Round Pipe Roll Forming Machine With 40/60/70mm

| Application | Windows And Doors Rolling Shutters System | Material | Galvanized Steel |

|---|---|---|---|

| Production | One Machine To Produce 3 Sizes Via Quick Change Cassette | Rollers Material | SKD11 Or Cr15 Mould Steel |

| Hardness | HRC58~62 Degree, Chromed | Guarantee | 5 Years |

| Punching System | Mechanical Press Punching Machine With 25 Tons Capacity | ||

| Highlight | tube roll forming machine,steel pipe making machine |

||

0.4~1.0mm Octagonal Tubes Round Pipe Roll Forming Machine With 40/60/70mm

1, Running material: Galvanized steel 0.45mm~0.6mm for 40mm tube ; 0.6mm~0.8mm for 60mm tube ; 0.8~1.2mm for 70mm tube

2, Forming speed: 6-10m/min (Punching is included)

3, Forming stands: 20

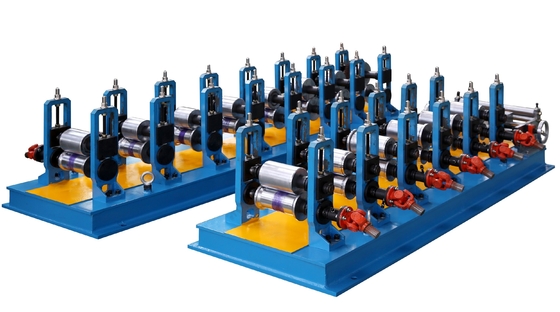

4, Roller material: CR15,HRC 58~60 degree. Roller diameter φ120,Maximal roller diameter:φ200

5, Material of shaft: #45 steel, china standard

6, Transmission system: Chain or gear box. Optional

7, Motor power: 7.5KW

8, Cut-off system: Flying saw cutting system

9, Material of molding reamer: Punch holes; Material of cut :Cr12Mov;Quench: HRC58-62.feeding speed is 6—10m/min Mechanical press machine: 25 tons capacity.

10, Fly saw cutting motor power : 4 KW

11, Control system: Touch screen is brand of Delta;Encoder is Omron brand; the Inverter is the Delta brand; others low voltage electric components are Schneider brands Germany.

12. Overall Dimension: 16000mmX1000mmX900mm

13. Total weight: 12 ton approximately

40mm and 60mm and 70mm Octagonal quick change cassette system